Coffee and Tea | Fall 2023

Skill Development: design and trend research, sketching, adobe photoshop, keyshot CAD modeling, prototyping.

the f!ka☼brew set

A Home Cold-Brew System inspired by Swedish Design Tradition with a turn towards Modern Coffee Trends and Ease of Use for new Fanatics.

Why Sweden?

Sweden is the Leading Country in Coffee Consumption worldwide.

Coffee is a Swedish way of life. The Swede's even have a name for pausing and taking a break for coffee, 'fika'.

Scandinavian Design has a passion for Sustainability.

Their design reflects “Nordic” principals. This calls for a connection to nature and minimilism, inspiring the final materiality.

Swedish product designers prioritize ergonomics and user comfort.

A major focus for the FᴉkaBrew ☼ design became a goal for user-friendly products and easy handling for any past user or new cold brew coffee brewer around the world.

Cold Brew Coffee has grown as a recent trend in Sweden and Worldwide.

Below is a task analysis of this process.

This analysis prompted thinking on new solutions. Looking for something that would make this process cleaner, easier, and would also look good when sitting in the refrigerator for the 12-24 hour weekly/daily process.

For Who? The Modern Cold Brew Enjoyer.

Inspiration.

Diving deeper in Swedish Design. Looking at Several Swedish brands have gained international recognition for their product design. Brands like IKEA, Volvo, H&M, and Ericsson have become synonymous with Swedish design and innovation. Looking at shapes and materials that embrace the Functional Minimalism design style.

Ideation.

Jumping into sketching and ideation, looking to follow the organic forms seen in the design research. Aiming to design the main feature: a cold coffee brewer, along with a cup for casual relaxed sipping (smaller), an on-the-go cup (taller and thinner), and a place to store and gather the coffee beans for frequent use.

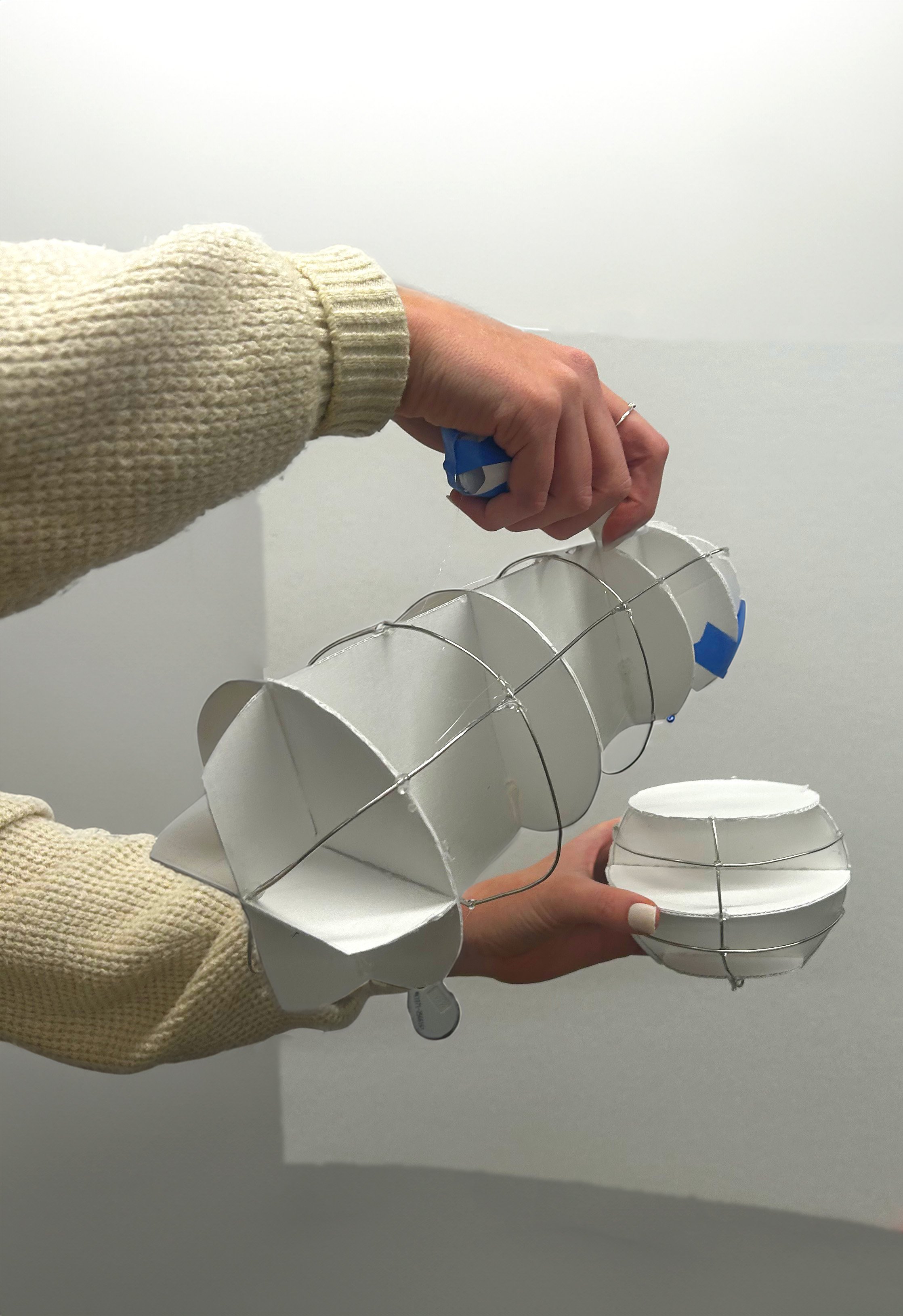

Sizing Prototypes.

Looking only at the sizing for the first prototype. Finding out which handles were successful and which pieces needed to be scaled down or sized up for the final model.

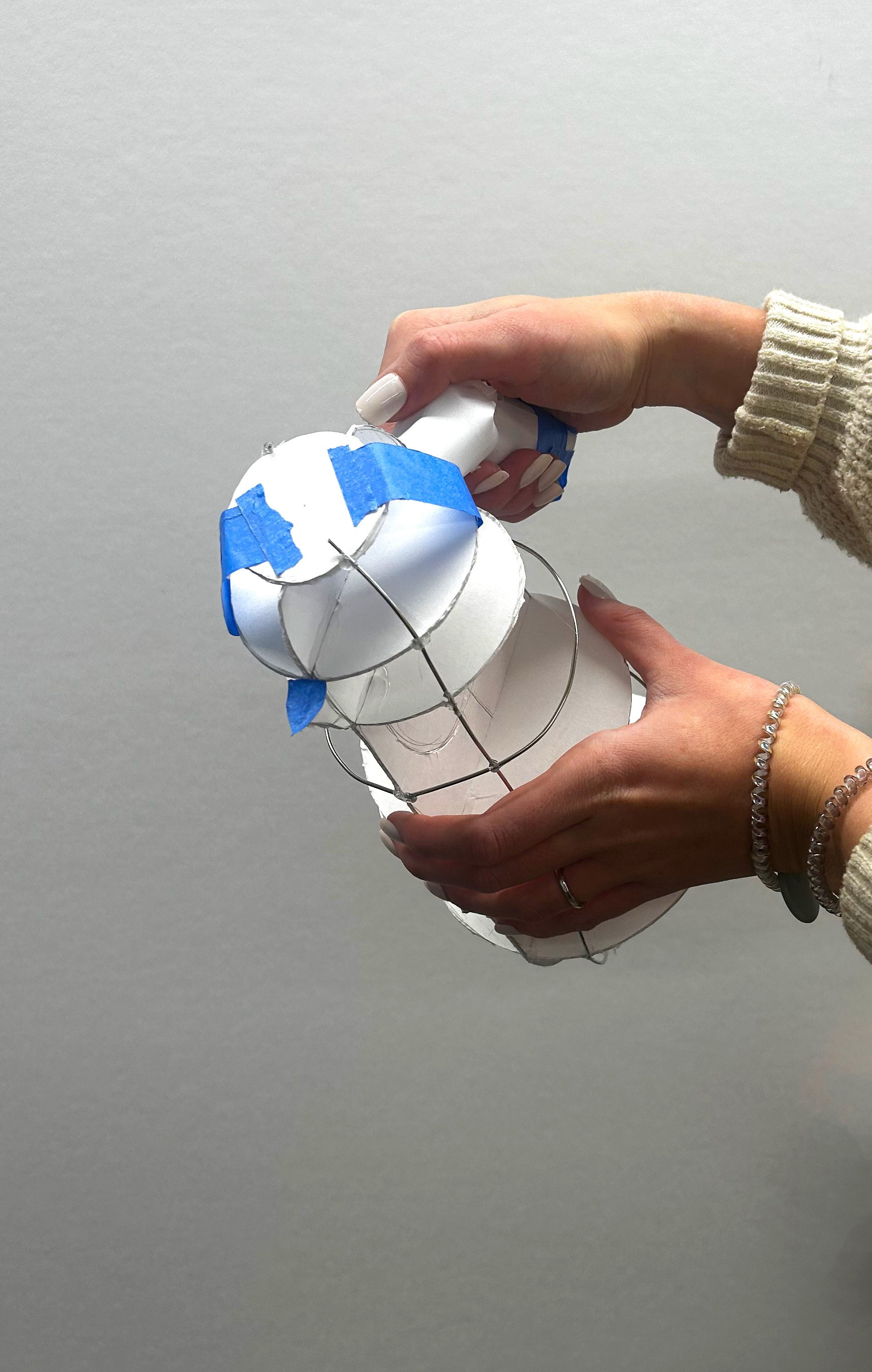

Volume Prototypes.

Moving onto the next prototype: looking at the volume of the final product. Discovering the overall form and seeing what works best aesthetically.

Task Analysis Prototypes.

The prototype was a full-focus on the final user system. Looking at all aspects of the task analysis and determining the ergonomic qualities of different pieces.

The pour test displayed that the angled handle was working as planned. Peer and personal input tested that the brewer could be poured with ease and comfort.

The tall and thin glass, paired with a straw, fit well in the hand, however the study showed that the piece could be expanded in scale slightly for the final design.

The small round glass mug, made for sipping, proved to be slightly too large for handling, it prompted the exploration of scaling down or adding handles/coaster.

Materiality Research/Ideation.

Why Glass?

Glass excels has a strong chemical resistance against water, saline solutions, acids, alkalis and organic solvents, and exceeds most plastics in this regard. Glass also adheres to the Nordic design values, creating a feeling of airiness and connection to nature making it commonly used in Swedish/Scandinavian design.

Why Wood?

Wood also supports design traditions of Scandinavia; oak wood is used most commonly. With the complex curves in this design and hand carved wood being unable to be mass produced, WPCS were chosen. Mold wood-plastic composites (WPCs) come with a significantly lower carbon footprint than petroleum-based materials. WPCs can be formulated using exclusively reclaimed wood fibers, again adhering to the sustainable design practices seen in Sweden.

Final Physical Modeling Process.

Priming each piece with sand-able primer to fill imperfections before doing each sand grit rise.

4 coats.

Using glazing spot putty on rough surfaces to be sanded down in process.

Sanding starting from 120 and working up to 1000 grit. Priming in between every couple hundred grit rises.

Final Models.

Finally using ultra white matte paint for the final clean and smooth model and sanding with 1200 grit in between the two layers.

2 coats.