Power Tool Project | Summer 2024

Redesigning the Electric Nail File with an added electric dust collector for the Revlon Brand Identity. Focusing on safety features, ergonomics, portability, and perception of value.

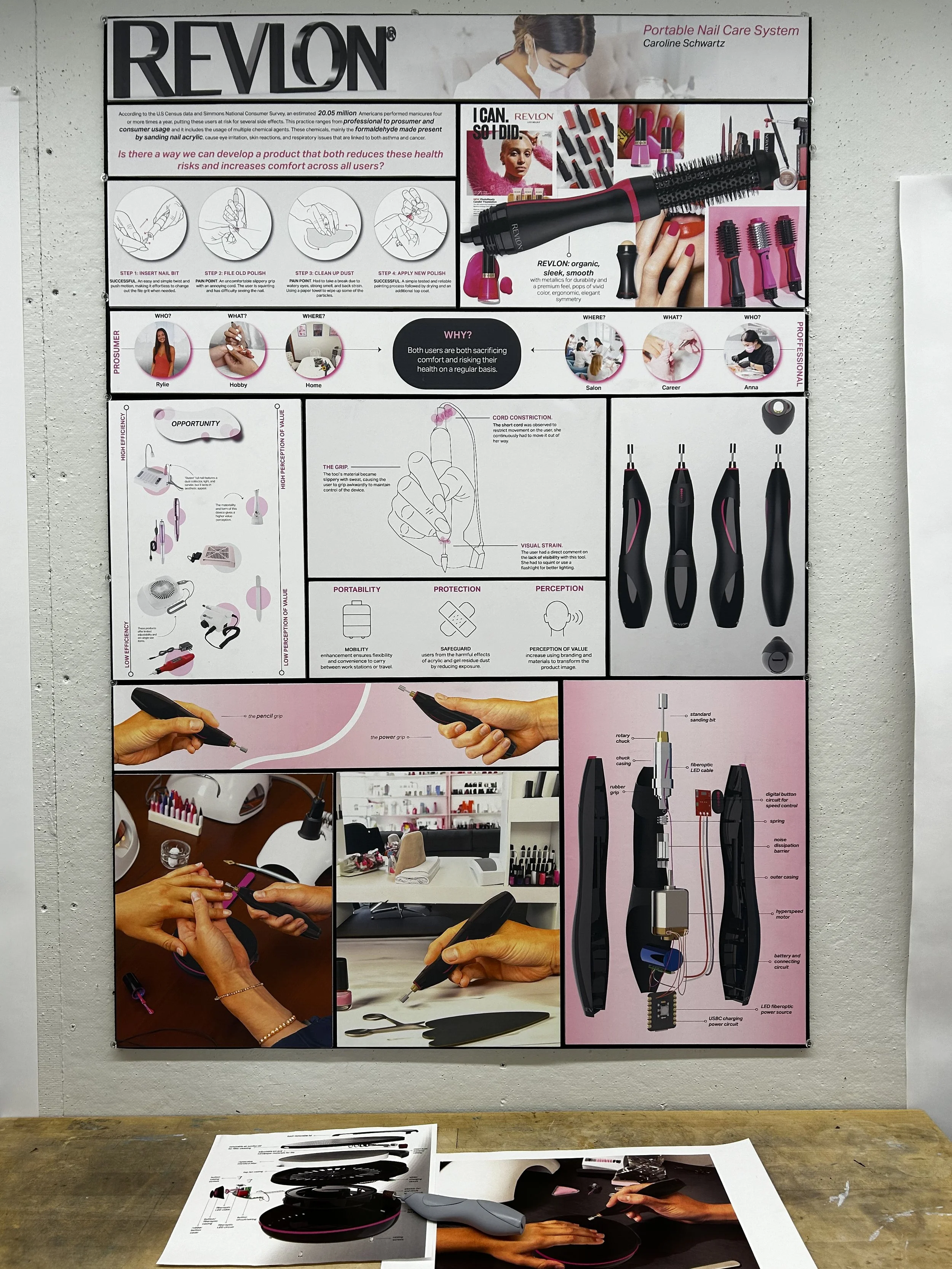

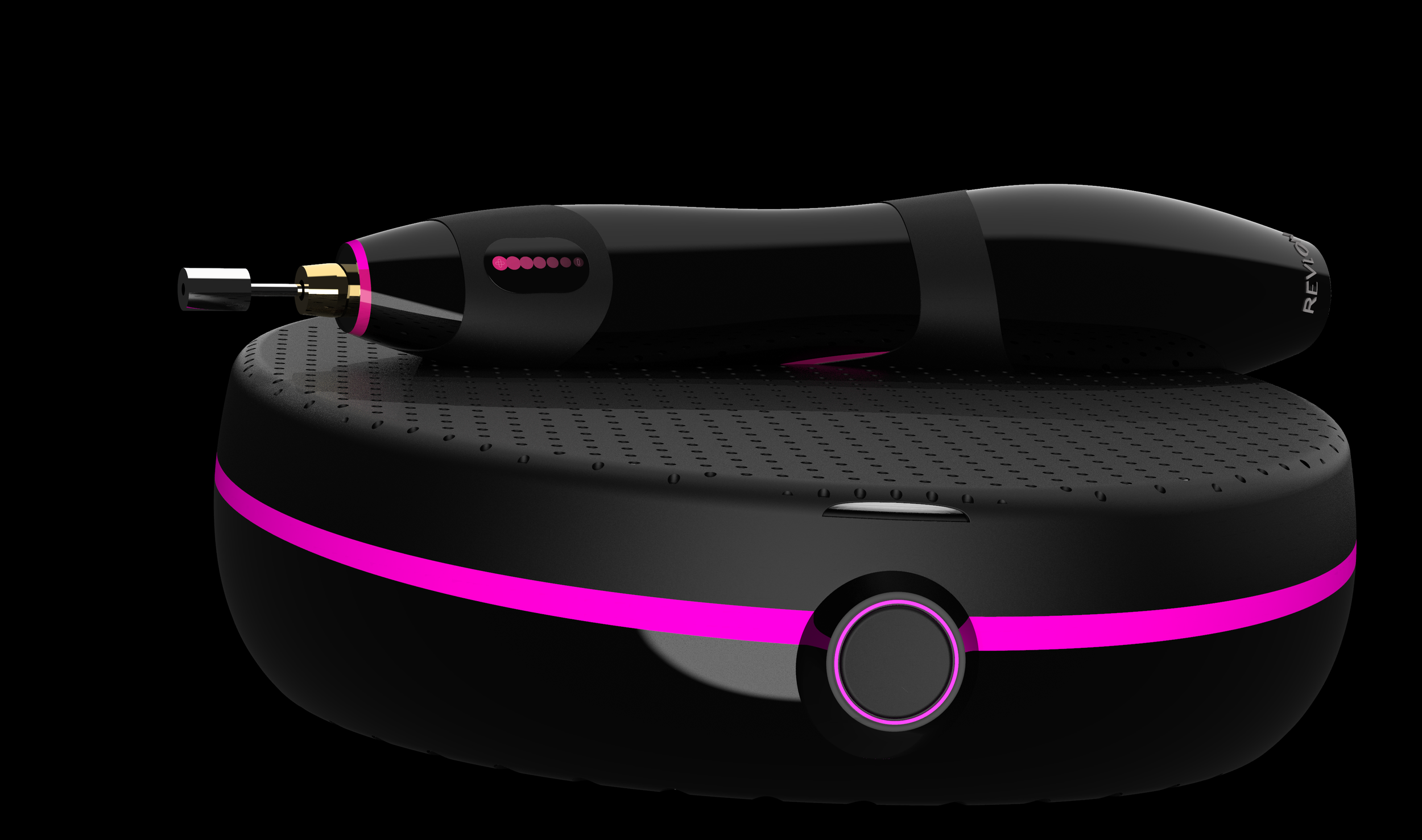

The Revlon Nail Care System

According to the U.S Census data and Simmons National Consumer Survey, an estimated 20.05 million Americans performed manicures four or more times a year, putting these users at risk for several side effects. This practice ranges from professional to prosumer and consumer usage and it includes the usage of multiple chemical agents. These chemicals, mainly the formaldehyde made present by sanding nail acrylic, cause eye irritation, skin reactions, and respiratory issues that are linked to both asthma and cancer. Is there a way we can develop a product that both reduces these health risks and increases comfort across all users?

User Immersion and Observation.

Task Analysis.

Observing the user in person, studying their habits and gaining feedback on the user experience. Analyzing to define the pain point.

Ergonomic Analysis.

Human Factors Analysis.

Studies on the effects of inhaling acrylic and gel dust particles along with ergonomic reflection of common sitting positions.

Market Analysis.

Researching the competitive market, looking for areas of opportunity in the nail filing space.

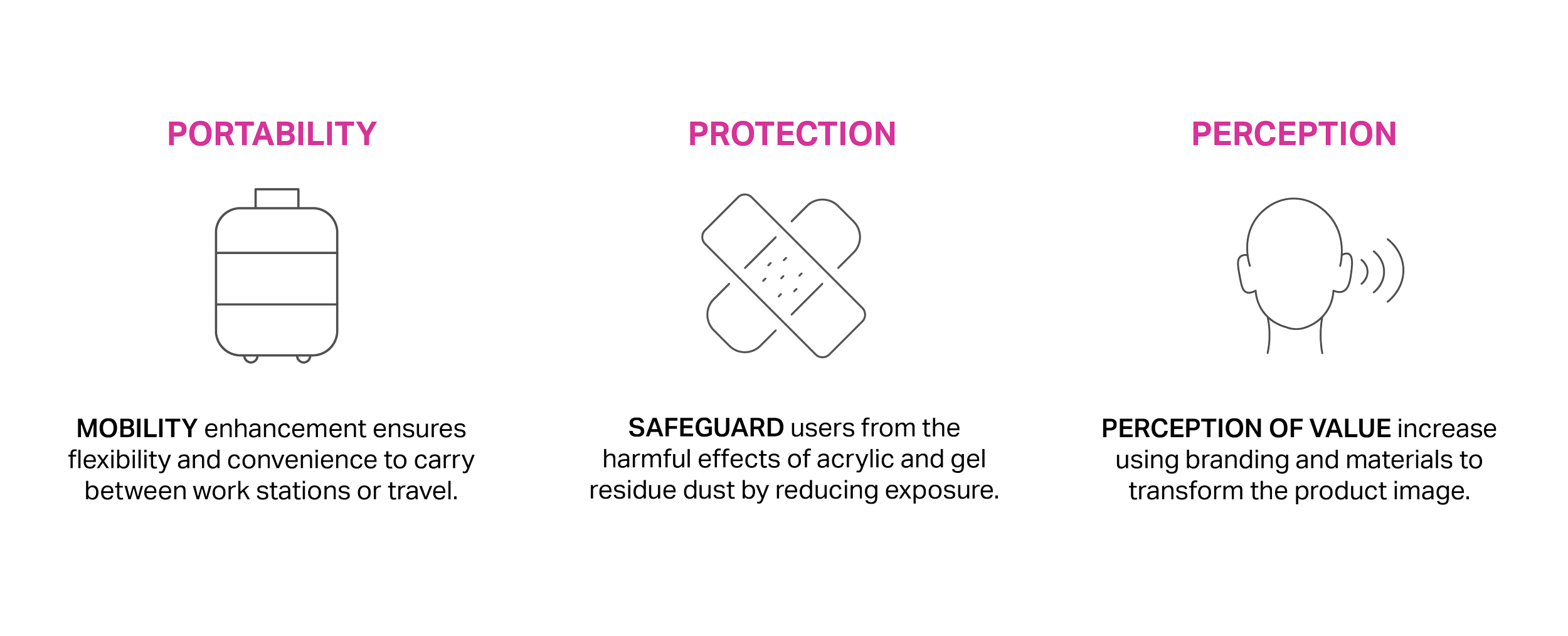

EFFICIENCY VS PERCEPTION OF VALUE

SAFETY FEATURES VS PORTABILITY

Defining Objectives.

Defining Brand Language.

Investigating the brand Revlon for its reputation of reliability and luxury, synonymous with quality in the beauty, haircare, and nail market. Revlon is known for emphasizing bold, vibrant, and stylish design. They have a track record of creating products that embody elegance, user-friendliness, and innovation, which could fuel my goal to raise the perception of value for this product through advanced performance and aesthetics.

Inner Component Breakdown.

Carefully disassembling my analogous tool, the Coslus brand electric nail drill and documenting its components and structure, noting parts in an exploded knolling style layout.

Ideation.

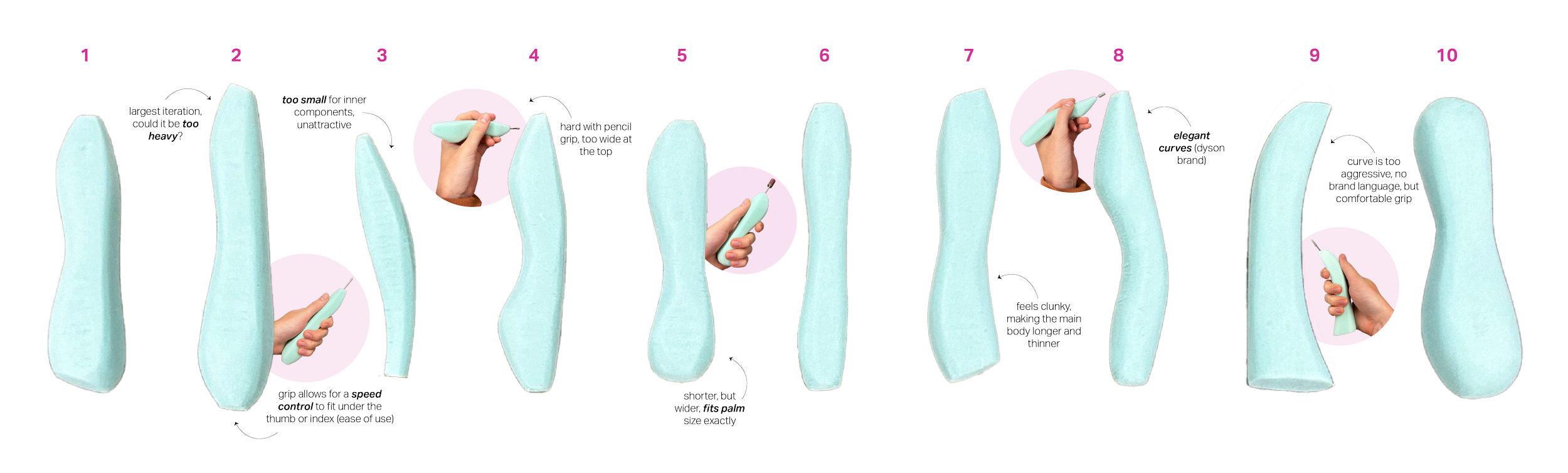

3D Model Testing.

Creating to scale models using foam for ergonomic testing. Beginning with ten original designs and following with deeper refinement and exploration based on user testing.

What about Safety?

A major objective in this product is the protection from unsafe dust particles. Originally thinking to add a vacuum into the file, however research displayed that was not possible with current technology. Deciding to look into a dust collector, starting with breaking apart the inner components. Then sketching ideation for a fan design to align with the file.

Aesthetic Ideation.

Bringing to Life.

To finalize the project, work began working in CAD on Fusion 360. Once the mechanism and CAD files were successful, the files were rendered in Blender and Keyshot.

The Final Presentation.

After size testing in the Bambu printer, the fusion file was sent out for resin printing and led to final prototyping for a clean physical model. Finally, poster conceptualizing for the final presentation began before constructing the poster for the end of semester critique.

THE FINAL PROTOTYPE.

Starting with a black resin print which was primed and sanded multiple times until smooth (working to 4000 grit and steel wool) to create a weight consistent model with consistent materiality and real bit attachment possible.

THE FINAL POSTER.

Creating ten original poster thumbnails (2 rounds), balancing feedback from peers and professors in critique. Creating two full scale mock-ups before printing and mounting the final onto sticky foam board and then onto black foam core for a 3D display.