Gear Studio | Spring 2025

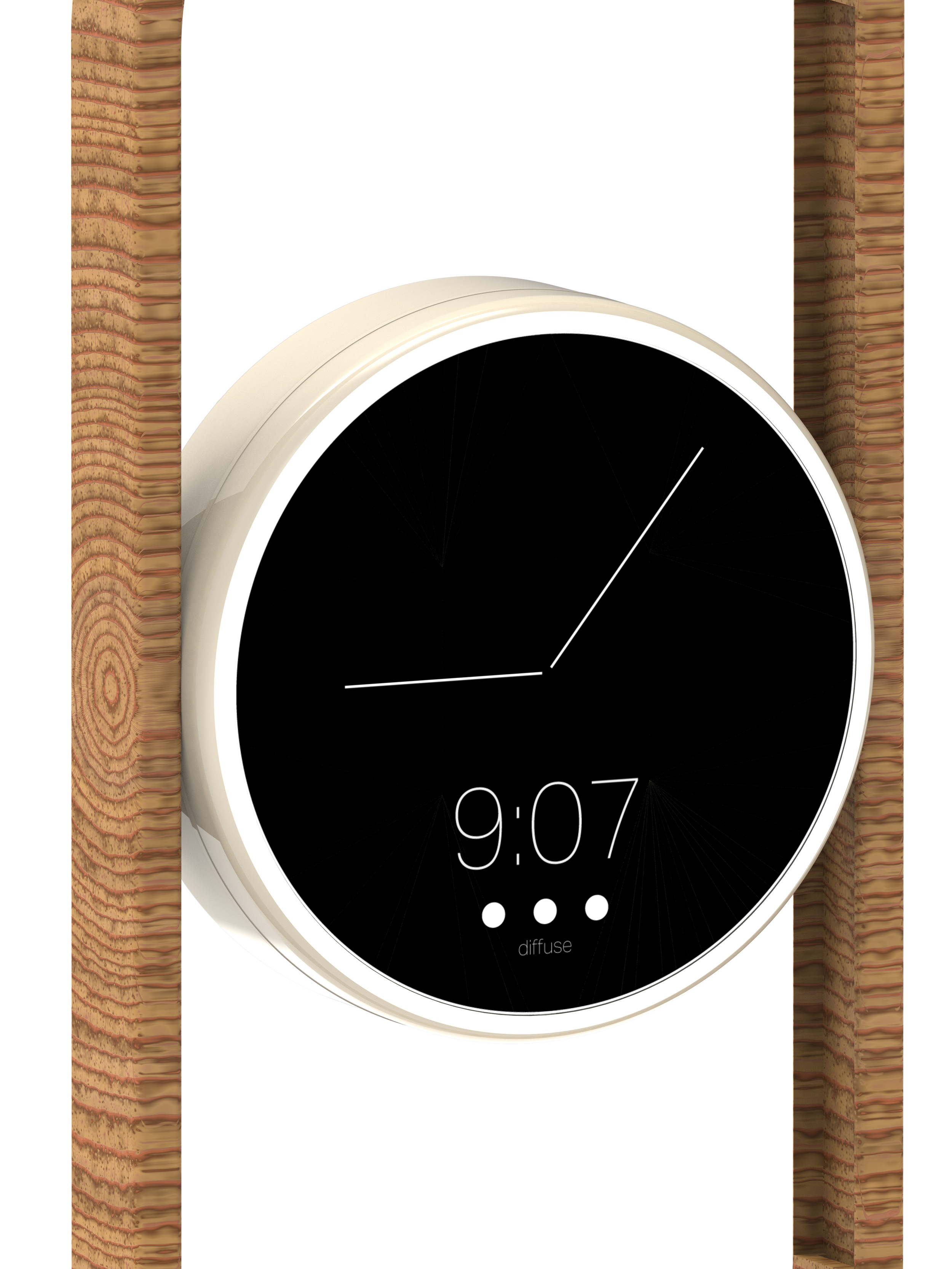

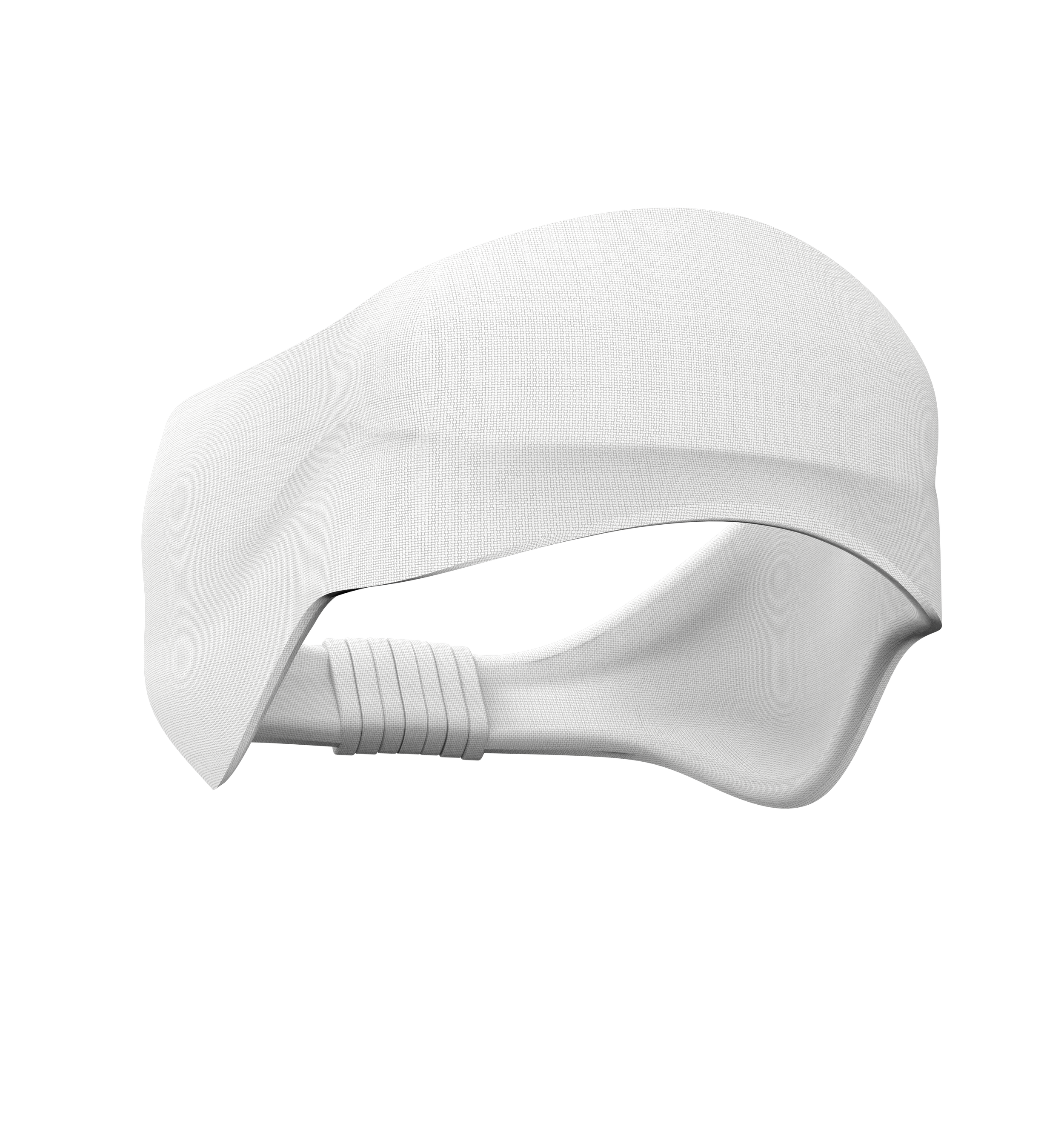

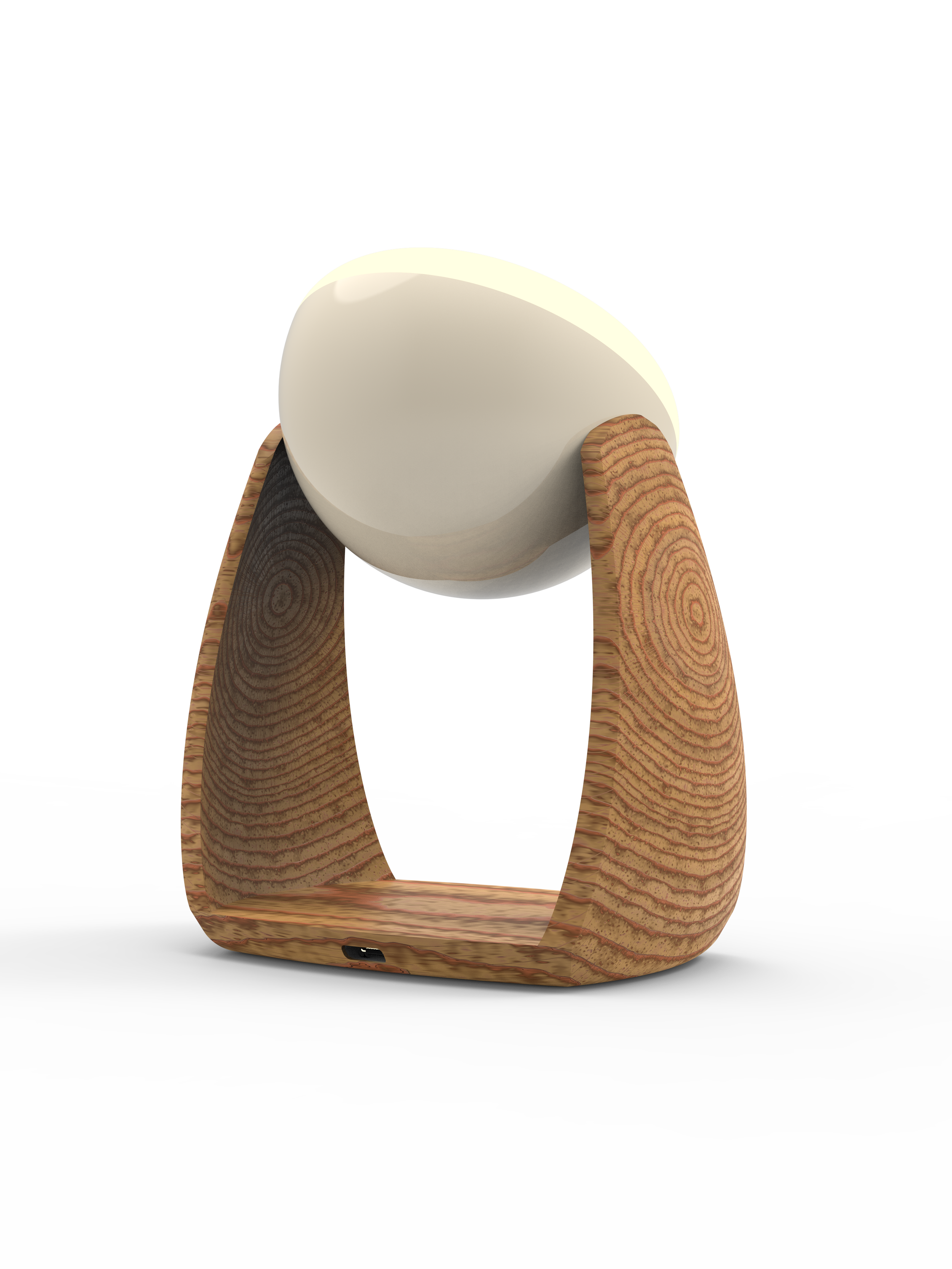

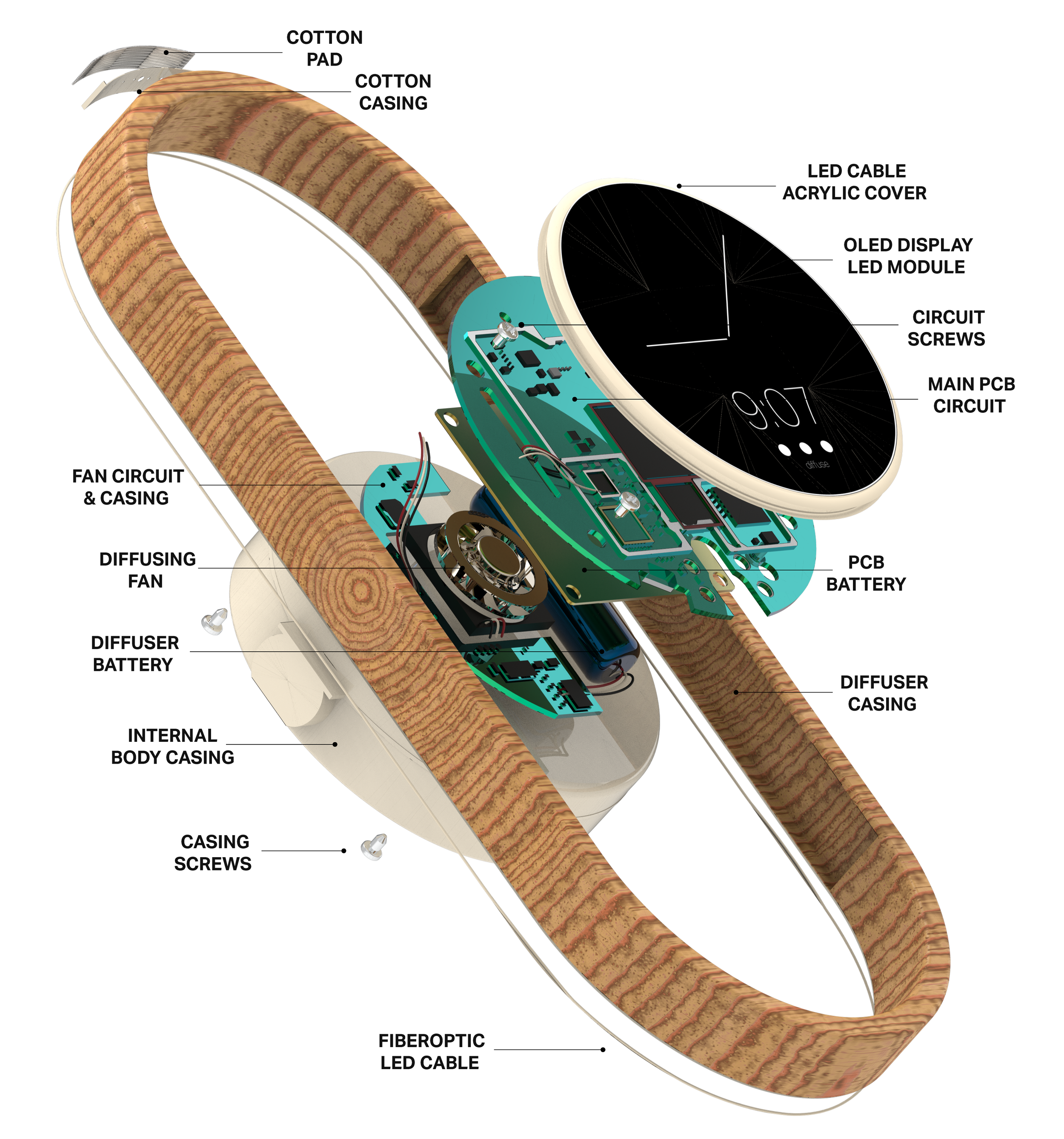

A multi-functional sleep aid system with a bluetooth synced diffuser, alarm clock, and sleep mask. Product based on large-scale consumer trends for every user from the occasional light sleeper to long term insomniacs.

The PhillipsxCalm Sleep Solution

Most adults need 7 hours of sleep per night, however according to the CDC, nearly 1 in 3 Americans do not reach this guideline and show significant symptoms of Insomnia, the most common sleep disorder today. Lack of sleep can contribute to health issues like obesity, diabetes, and heart disease. With this rise in sleep disruption, there has been a growing upcoming trend surrounding "sleepmaxxing” which challenges people to optimize their sleep quality. Previously, the global sleep aids market was valued at $64.3 billion in 2021, however it is now projected to grow by 6.2% through 2030. This projected increase is driven by this growing cultural awareness of the importance of quality sleep, along with rising anxiety and stress levels amongst young adults.

Is there a product we can create that could meet the demand of this rising market trend while also aiding in the “sleep fitness” of everyday consumers?

Phase I | Interviews & Research.

For and more in depth look into my Trend Research, click below!

*

For and more in depth look into my Trend Research, click below! *

Phase II | Defining Opportunity.

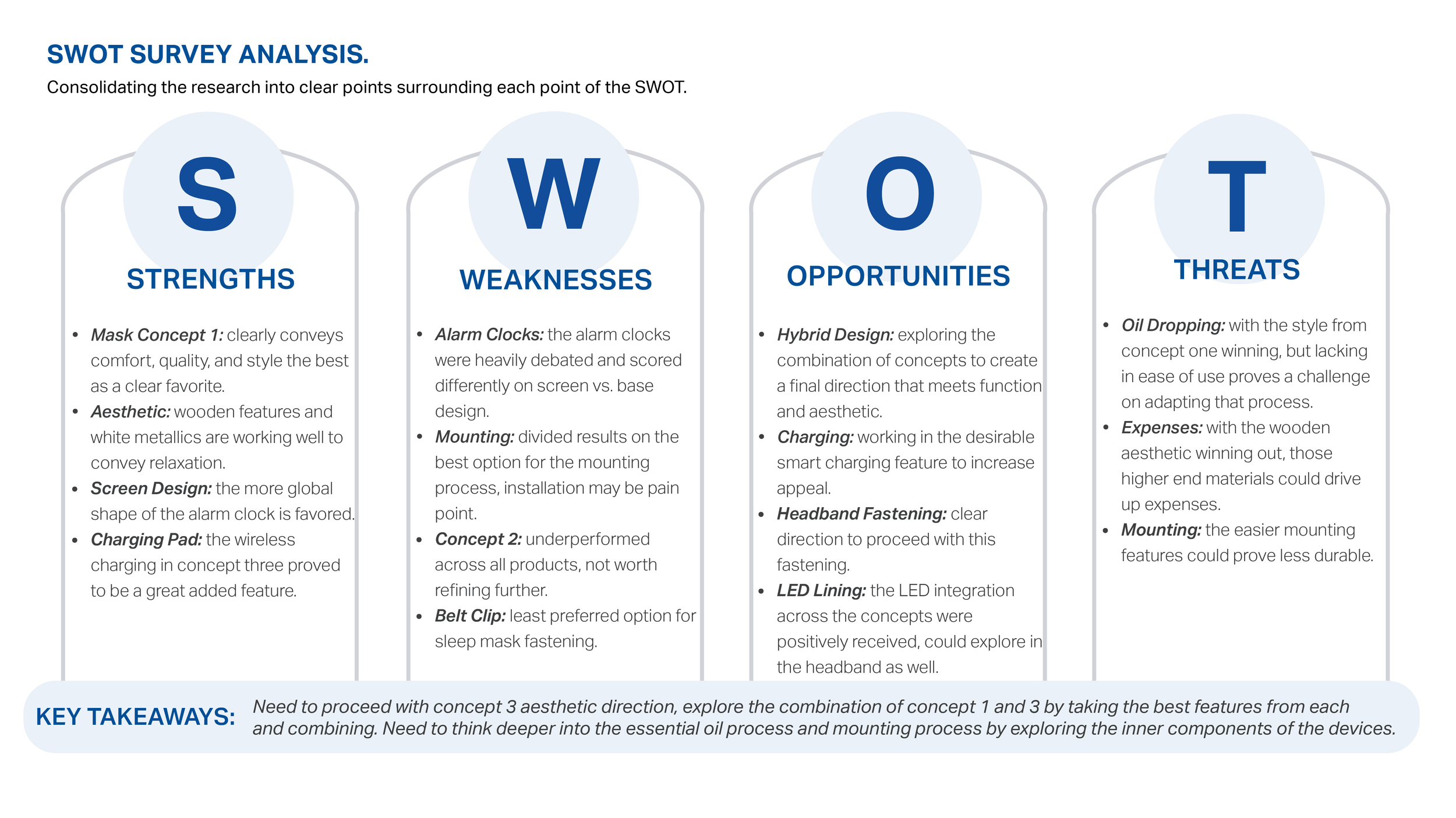

Phase III | Conceptualizing & Consumer Feedback.

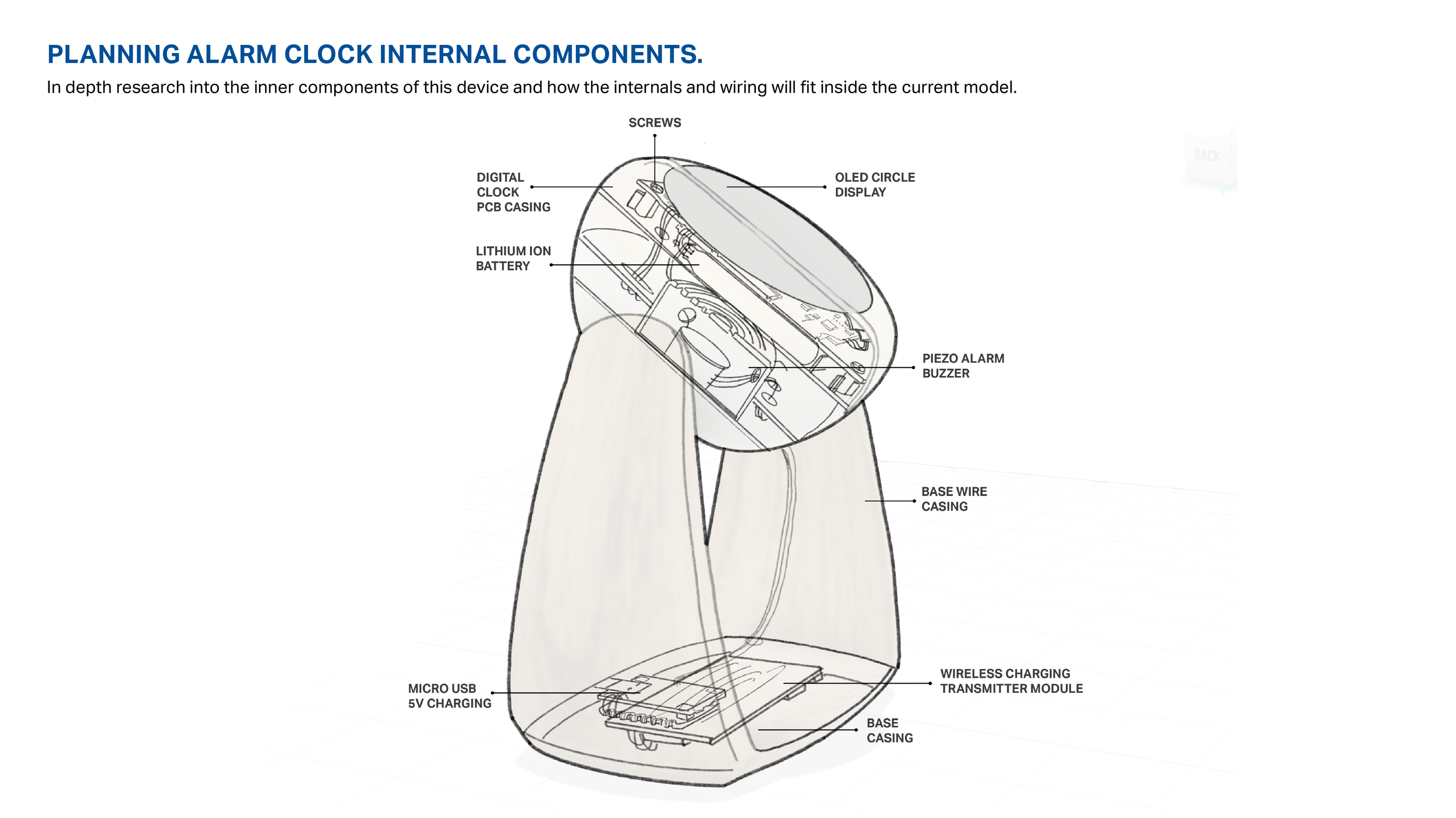

Phase IV | Refining and Defining.

DEFINING BRAND LANGUAGE: PHILLIPS X CALM.

Bringing to Life.

To finalize the project, work began working in CAD on Fusion 360. Once the mechanism and CAD files were successful, the files were rendered in Keyshot, Vizcom, and Photoshop.

The Final Presentation.

After protyping the final 3D files were printed and were finished for a clean physical model to pair with the finished mask. Finally, poster conceptualizing for the final presentation began before constructing the poster for the end of semester critique.

THE FINAL PROTOTYPE.

Reworking the alarm sizing and finishing the final models. I did four coats of primer, sanding up from 120 to 3500 grit throughout the week and using spot putty when needed. Wet sanding at 4000, and finishing with 3 coats of white matte paint.

THE FINAL POSTER.

The poster criteria was to have a section of research and reasoning, a title, process work, and presentation of the final system. I started working on the layout first, and adjusted sizing and type size based on testing it to scale on the monitor.